Promoting innovation, optimizing processes!

Digital transformation in discrete manufacturing

Create room for innovation by establishing reliable, resilient supply chains and using AI-powered processes to automate and optimize your production operations.

Digital and transparent processes

Manufacturing processes as a success factor

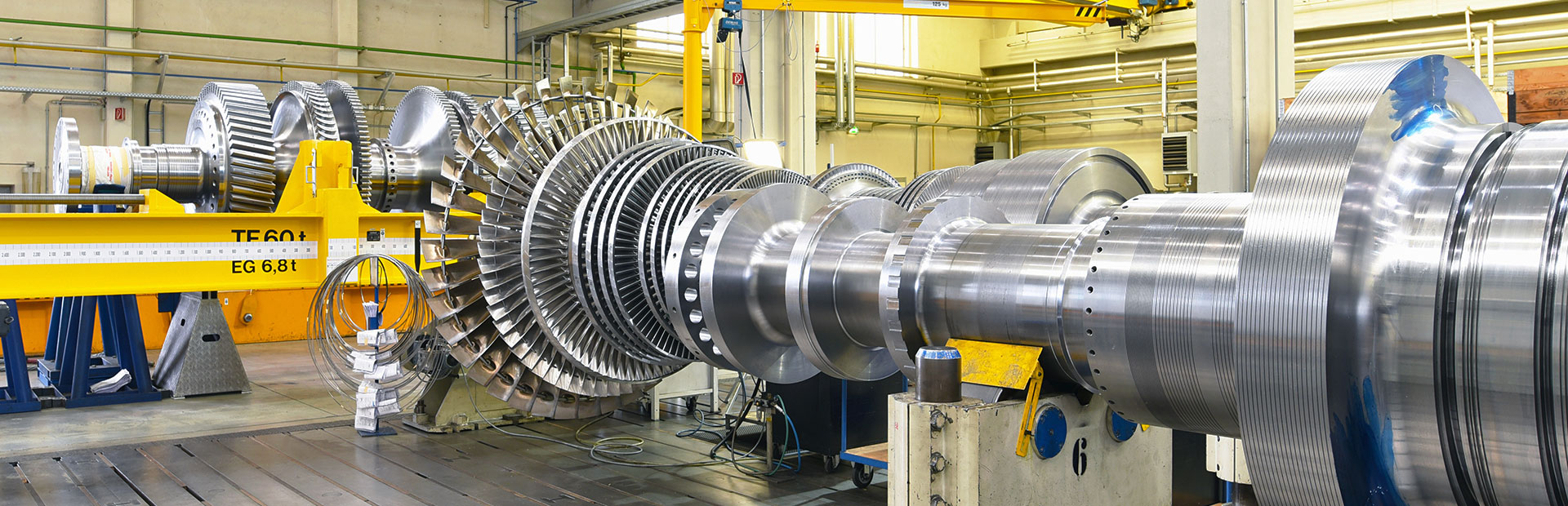

The production of end products in discrete manufacturing, is characterized by the generation from individual components, materials and raw materials. Therefore, the manufacturing process represents one of the decisive factors for success!

The upstream and downstream processes, from product development and cost accounting to after-sales, must also be taken into account. This requires processes that are as digital and transparent as possible in order to have an overview of the respective statuses at all times and, if necessary, to be able to intervene quickly and implement the necessary adjustments.

Safety through agility

Small changes with big impact!

Adaptability through digitalization!!

Our fast-moving everyday life is characterized by a networked, strongly varying environment, even small changes can have a big effect. Therefore, the trend in production is increasingly moving towards small batch sizes and shorter product life cycles!

By using digital technologies, you can transform your company into an agile factory and are able to react very quickly to rapidly changing situations.

Proactive maintenance

Deepen your customer relationships!

Delight your customers by using IoT technologies to remotely detect potential failures, provide predictive services, and reduce downtime.

Increase first-time-fix rates and optimize services!

Support your field service by providing relevant information at the right time and connect service staff on-site, via Mixed Reality with remote experts to improve your first-time-fix rates.

Use AI-optimized scheduling to help your dispatchers efficiently utilize your technical staff and meet existing SLAs.

Further enhance your service offering by establishing omnichannel and self-service customer support!

Achieving high efficiency

Optimize production steps and make maintenance work efficient!

Highlights at a glance

Financial Management

- G/L accounts, accounts receivable / payable, payment processing, budgets, compliance management.

- Organization management, employee management, development, training and performance evaluation, travel expense reporting.

- Project controlling, work breakdown structures, project hierarchies, project accounting and invoicing, integration with MS Project.

Supply Chain Management

- Optimized workflows, rapid product supply, easy automation, predictive analytics.

- Flexible manufacturing processes using IoT and reduced downtime through predictive equipment maintenance using AI-powered processes.

- AI-powered sales forecasting, to avoid surpluses/shortages and increased efficiency.

- Optimized asset management, IoT & Mixed Reality, reduced equipment wear and precise maintenance planning.

Maintenance

- High customer satisfaction through personalized and on-time services, using IoT and AI-powered processes.

- Improved first-time-fix rates and increased productivity of your employees, through provided knowledgebase articles and remote support from experts in real time via Mixed Reality.

- Real-time, up-to-date asset data to optimize your machine utilization and reduce downtime through predictive maintenance management, using IoT sensors and AI-powered service processes.

Sales activities

- Increased revenue through the use of collaborative, insight-based sales solutions.

- Optimized sales cycles using AI-powered sales action suggestions.

- Improved prioritization of your customers and targeted activities with the highest probability of closing a deal.

- Improved predictability of your sales focus and activities for all sales channels, through AI-powered, experience-based predictions of sales fluctuations.

- Real-time data on current sales trends and probabilities.

Marketing

- Merge contact histories based on real-time cross-channel interactions, such as: Email, web forms, and text messaging (SMS).

- Forcing customer activity, by sending reminders and resending messages.

- AI-powered, personalized messages that automatically include the right content for each customer.

- Using AI-generated content such as: Images, dynamic content or offers.

- Efficient collaboration and improved interactions, through the use of integrated Microsoft Teams Chat, across the customer contact journey.

- Manage content across brands for emails and workflows by creating brand profiles and defining access at a global and local level to support brand, regional, and product line strategies.

Customer Care

- Increased customer loyalty through faster service, via your customers' preferred digital channel, whether via email, SMS, social networks or virtual assistants.

- Real-time translation, for communication in your customers' preferred language.

- Fast& tracking of customer issues, for quick resolution by your service agents.

- Networking of your experts, with the help of Microsoft Teams integration.

- Intelligent request swarming, for efficient resolution of complex requests.

- Accurate views of your customer center's performance parameters, to accurately track KPIs.

- Improve CSAT by identifying new trends to optimize support issues, interaction with your customers, and knowledge management.

Document Management

- Location and time-independent access to desired documents and media data.

- Conformity within the scope of compliance with all current legal regulations.

- Protection against unauthorized access, through a sophisticated rights concept.

- Document management and long-term archive integrated in one product.

- Complete integration in Windows, through patented technologies.

- Open interfaces, enable adaptations without restrictions.

- High user-friendliness and acceptance, through familiar working environment.

Electronic data interchange

- Central data exchange (orders, invoices, ...) with customers, suppliers, partners and their systems via EDI managed services interface.

- Seamless integration with your ERP system to improve transparency.

- Shortening of the order-to-cash cycle through process optimization.

- Fully redundant software, hardware and network components for best possible security.

- High protection against data loss, through robust and regularly tested disaster recovery capabilities including real-time switchover processes.

- High availability of services, through the combination of high-quality, high-performance hardware and network components.

We design solutions that fit your needs!

Would you like to be informed in detail about opportunities and possibilities for the successful digitization of your company?

We will be happy to advise you!

+43 50 46743329

office@insideAx.at